Residential:

Structural Insulated Panels (SIPs) provide superior

energy efficiency and labor cost savings

Learn More

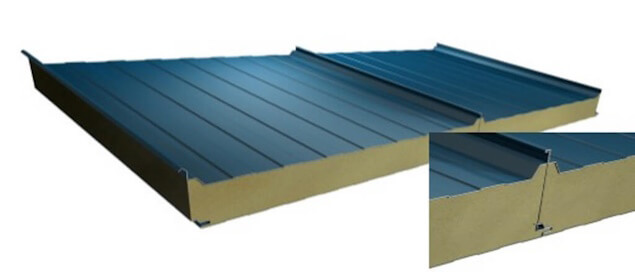

Insulated Panels For Your Roof:

Protect your home or commercial building

from the elements with these insulated roofing options

Learn More

About Us

Our facility is located in Cassville, Missouri. We have over 35 years combined experience in manufacturing, distribution, and installation of a variety of insulated panels and accessories for the commercial and residential construction industries. We pride ourselves in giving the best customer experience possible.