ADVANTAGES OF SIPs PANELS VS STICK BUILT HOMES

Speed of Construction:

Our SIPs are manufactured in our Cassville plant. Each panel is cut to size, including the specified window and door openings, before shipping to the job site. We can then easily and quickly assemble your home on site. With this method of construction we can reduce dry-in time from weeks or months for stick-built construction to a matter of days. This can give you a significant savings in labor costs.

Fewer Air Leaks:

In conventional stick-framed construction, cellulose insulation settles and compacts over time. This results in a reduction over time in the R-value and energy-efficiency of your home. However, the solid foam core of a SIP panel will not settle or compress. This means that a SIP built house will maintain its R-value and energy efficiency throughout the coming years. In addition, building with SIPs creates a much tighter building envelope resulting in less air infiltration. This will greatly increase the energy efficiency and comfort of your home. The result is a significant cost savings on utilities over the life of your new home.

Reduced Thermal Bridging:

Thermal bridging is the term used when heat and cold are transmitted through an object. Dimensional lumber (2x4s, 2x6s) are a poor insulator against this thermal bridging effect. The more dimensional lumber is used in a structure the more thermal bridging becomes a problem, reducing energy efficiency. A SIP panel contains a solid foam core which reduces the quantity of dimensional lumber used. This results in a reduction of thermal bridging and a significant increase in energy efficiency. Also, since you are using less lumber in SIP construction you are helping the environment by using fewer trees.

High R-Values:

A standard 6-½ inch SIP panel has an R-value of 26, while a 6 ½ inch stick-built wall with cellulose insulation has an R-value of 20. But there is more to the story…Continue reading.

R-value of 20. But there is more to the story…Continue reading.

Greater Strength:

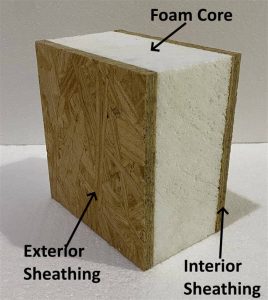

We glue SIP rated OSB to both sides of the foam core with a commercial grade urethane glue. This creates an extremely strong panel assembly that is similar to an I-beam. These panels are highly resistant to shear loads (external force that produces sliding failure between two parallel surfaces) and racking (when a building moves out of plumb or alignment). Simply put, SIPs construction can withstand high winds and seismic activity better than conventional stick-built construction.

Return to “Structural Insulated Panels“